节能型振动流化动态干燥机 Energy-s**ing Vibro Fluidized Dynamic Drier节能型振动流化床

品牌

其他厂商性质

成都市所在地

湿法造粒机Wet Pelletizer

面议

臭氧灭菌柜Ozone Sterilization Oven

面议

圆盘造粒机Disc Pelletizer

面议

摇摆式颗粒机Swing granulator

面议

螺杆挤压造粒机Screw Extruding Pelletizer

面议

百级干热灭菌柜One-hundred Grade Dry Heat Sterilization Oven

面议

旋转制粒机Rotary Pelletizer

面议

高温连续动态煅烧(聚合)设备High-temperature Continuous Dynamic Calcination (Polymerization) Equipment

面议

高温箱式静态煅烧(聚合)设备High-temperature Box-type Static Calcination (Polymerization) Equipment 高温静态煅烧

面议

干法挤压成型造粒机Dry Extrusion Forming Pelletizer

面议

固体熔融冷却造粒机Solid Melting and Cooling Pelletizer

面议

碾压制粒机Grinding Pelletizer

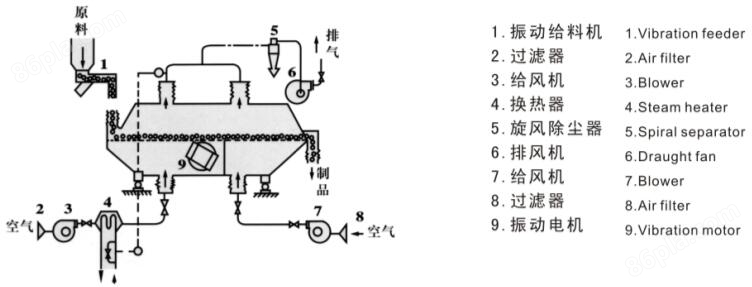

面议物料从进料口进入床体内,床体振动电机或其他方式提供的激振力作用下作一定频率的振动,先经过滤净化然后经加热到一定温度后的热空气经入风口进入干燥机下风分配室然后再均匀穿过流化床板,物料在振动分散力和经空气分布板均风的热气流双重作用下,呈悬浮状态与热气流接触,物料颗粒与热介质之间进行着激烈的湍动,使传热和传质过程得以强化,干燥后的产品由排料口排出,蒸发出的水份和废气经旋风分离器回收粉尘后,排入大气。下床体为床层提供了一个稳定的具有一定压力的风室。调节引风机,使上箱体中床层物料上部保持微负压,维持良好干燥环境并防止粉尘外泄。

振动流化床干燥机用于颗料状、粉末状物料干燥的新型流态化高效干燥设备,适用于化工、制药、食品、脱水蔬菜、粮食、矿产等行业。也可以用于物料冷却、增湿作业。该机组能大批量、长期连续的进行生产。节能型振动流化床

Material enters the bed via the feed opening and vibrates at a certain frequency under the exciting force provided by the vibration motor of bed or in other way; the hot air which is filtered and purified firstly and subsequently heated to a certain temperature enters the drier downwind distribution chamber via the air intake vent and subsequently runs through the fluidized bed plate. Under the dual action of the vibration dispersion force and the hot air distributed uniformly by the air dispersion plate, the material in the suspending state contacts with the hot air. The drastic turbulence between the material particles and the heat media enhances the heat and mass transfer process. The products dried are discharged via the discharge opening; water and waste gas are discharged to the atmosphere after dust is collected by the cyclone separator. The lower bed provides a stable air chamber with stable pressure for the material layer. Induced draft fan is adjusted to maintain tiny negative pressure at the top of the material in the upper box so as to keep a good and dry environment and prevent dust from escaping. The vibro fluidized dynamic drier is a novel fluidized high-efficiency drying equipment used for drying pelletized and powder-like materials. It is suitable for such industries as chemical engineering, pharmaceuticals, food, dehydrated vegetables, grains and minerals, and also suitable for material cooling and humidification operation. This unit can be put into mass and long-period continuous production.

1.物料受热均匀,热交换充分,干燥强度高,比普通干燥机节能30%左右。

2.可调性好,适应面宽,料层厚度和在机内移动速度以及全振幅变更均可实现无级调节。

3.振动源是采用振动电机驱动,运转平衡、维修方便、寿命长。

4.振动有助于分散湿含量大、易团聚、粘结的颗粒,改善流化状态,流态化稳、均匀,无死隙和吹穿现象,可以获得均匀的干燥、冷却、增湿效果。

5.对颗粒物的破碎以及磨损较少,可用于易碎的干燥,物料颗粒不规则时亦不影响工作效果。

6.由于施加振动,可使最小流化气速降低,因而可显著降低空气需求量,进而降低粉尘层夹带,配套热源,风机,旋风分离器等也可相应缩小规格。

1.The material is heated evenly with sufficient heat exchange and high drying intensity. Its energy saving is 30% higher than the ordinary driers.

2.It has great adjustability and wide applicability. The thickness of material layer, the running speed in the drier and the change of double amplitude are step-less controllable.

3.Vibration is driven by the vibration motor featured by smooth operation, easy to repair and long service life.

4.Vibration is helpful to disperse the particles which have high moisture content and are easy to clot and cohere and improving the fluidized state, so that fluidization is stable and uniform, without dead space and blow-through, and uniform drying, cooling and humidification effects can be achieved.

5.It may make less particles crushed and abraded and can be used to dry the fragile particles. Its operating effect will not be affected even the particles of material are regular.

6.Vibration can reduce the minimum fluidizing air velocity, so the demand for air may decrease obviously and therefore dust entrainment will decrease. The sizes of supporting heat source, fan and cyclone separator etc may decrease accordingly.