品牌

生产厂家厂商性质

台北市所在地

粉体输送吸料机

| Feature | • The unit is designed for dust-free operation with using the Teflon filter bag. Filter efficient is 1µ. • Modules are designed for easy filter replacement and ensure unit the optimum easy cleaning. No tools needed for material changes or clean out. • This unit interior is easily accessible when the quick-action locks on the unit cover are released and the filter insert is removed. • The control panel can be either mounted on the hopper loader as standard or installed on the vacuum unit. • A self-closed flap mechanism with magnetic switch is fitted to the material discharge port underneath the hopper. • The numerous surface treatments are possible to meet the customer request. • There is a cleaning door with a filter cartridge fitted with hopper body in order to assist operation and maintenance of the flap mechanism. • Modules are quickly assembled using a hand clamping operation. • Purge a compressed air in the vacuum filter at a time, to clean and get rid of impurities which attribute excellent conveying performance and eliminate material packing. |

| Application | For all free-flowing bulk material, both powders and pellets. |

| 型號 | SP25 | SP50 | SP100 | |

| Hopper capcity | Liter | 25 | 50 | 100 |

| Filter surface | m2 | 0.42 | 0.54 | 0.66 |

| Compressed air | Kg/cm2 | 2~3 | ||

| Probe diameter | inch | 2 | 2.5 | 3 |

| Width | mm | Ø360 | Ø420 | Ø500 |

| Overall height | mm | 1100 | 1567 | Ø1826 |

| Weight, apporx. | Kg | 35 | 45 | 60 |

Single Hopper Loader![]() SN Series Hopper Loader For Non-Flowing Powders

SN Series Hopper Loader For Non-Flowing Powders

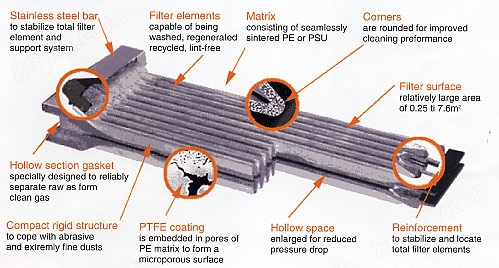

| Feature | • High dense-phase vacuum conveyor for fine powders. Use "sinter-plate" filters separation efficient up to 99.999%, and clean gas side particulate content ≤ 1mg/m3 S.T.P. • Impact, anti-corrosive, anti-statistic, water-proof and long working life, etc. • Fast assembly and disassembly for cleaning. Quick and easy module replacement. • Special design, lower air-purge consumption, and best air-purge cleaning efficiency. Installation and removal of the filter is possible on both sides by simply removing one screw. |

| Sinter-Plate |  |

| Purge a compressed air in the vacuum filter at a time, to clean and get rid of impurities which attribute excellent conveying performance. Modules are quickly assembled using a hand clamping operation | |

| Application | Titanium Dioxide, Pigment, Toner, Calicum Carbonate, Caron Black, Silica Sand, Cement, Phenolic Moding Compound, Epoxy Resin, Phenolic Resin, Zeolite, Glass Fiber Resin, Soda Ash Clay, Flyash, Limestone, Starch, Talc, Flour, Melamine Resin, etc. | |

| 型號 | SN25 | SN50 | SN100 | |

| Hopper capcity | Liter | 25 | 50 | 100 |

| Filter surface | m2 | 1.1 | 2.2 | 3.3 |

| Compressed air | kg/cm2 | 2~3 | ||

| Probe diameter | inch | 2 | 2.5 | 3 |

| Width | mm | Ø350 | Ø420 | Ø500 |

| Overall height | mm | 1370 | 1567 | 1826 |

| Weight, apporx. | kg | 40 | 65 | 80 |