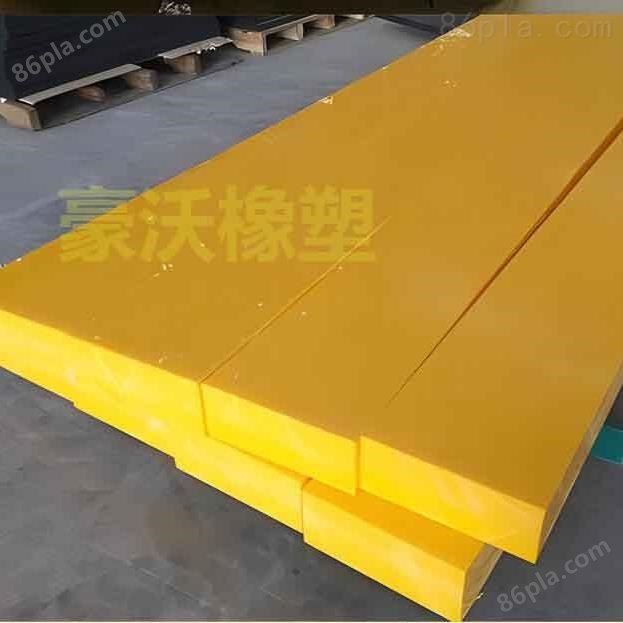

定制 机械设备用耐磨自润滑聚乙烯材质耐磨块滑块

产品简介

1.高耐磨性和抗冲击性 2.抗紫外线

3.易于加工以供工程使用 4.几乎不会受到化学侵蚀

5.低摩擦系数 6.不结块和粘附 7.良好的电气性能

8.在低温应用中表现出色温度:180华氏度 吸水率< 0.01%

详细信息

超高分子量聚乙烯的英文是:Ultra High Molecular Weight Polyethylene, 这是现有的可应用于恶劣工作环境及多种用途的聚乙烯。在许多高难度的应用条件下适用性非常好。,超高分子量是这种象合物与众不同的特质,其具有300至600万的分子星,而高密度类乙烯树脂只有30万至50万。这种差別是保证超高分子星聚乙烯具备的强度,以达到其他低等聚合产品所不可能具备的耐磨损和抗冲击能力。传统的塑料加工技术,比如注塑成型。吹塑和热定型,无法应用于超高分子量聚乙烯。挤压成型是应用于常见的加工工艺,这样生产出来的产品韧性强。

机械设备用耐磨自润滑聚乙烯材质耐磨块滑块

超高分子最聚乙烯 (UHMW-PE)是热塑性工程塑料。它综合了大部分塑料的优越性能,耐冲击、耐低温、耐磨损、耐化学腐蚀、自身润滑、吸收沖击能,这六个特性是目前塑料中所具有的数值,近年来这种新型塑料制品在欧美各国得到广泛使用,需求量越来越大。除了日常广泛的应用外,本品还可以根据用户的需要,通过改性或加工,以满足国民经济各个行业和部门的不同要求。

The English name for ultra-high molecular weight polyethylene is: Ultra High Molecular Weight Polyethylene, which is an existing polyethylene that can be used in harsh working environments and for various purposes. It has excellent applicability in many difficult application conditions., Ultra high molecular weight is a unique characteristic of this complex, with molecular stars ranging from 3 to 6 million, while high-density ethylene resins only have molecular stars ranging from 300000 to 500000. This difference ensures that ultra-high molecular weight polyethylene has sufficient strength to achieve wear resistance and impact resistance that other low-grade polymer products cannot. Traditional plastic processing techniques, such as injection molding. Blow molding and heat setting cannot be applied to ultra-high molecular weight polyethylene. Extrusion molding is the most common processing technology used to produce products with extremely strong toughness.

Wear resistant self-lubricating polyethylene material wear-resistant block sliders for mechanical equipment

Ultra high molecular weight polyethylene (UHMW-PE) is a thermoplastic engineering plastic. It combines the superior properties of most plastics, including impact resistance, low temperature resistance, wear resistance, chemical corrosion resistance, self lubrication, and absorption of impact energy. These six characteristics are currently present in plastics. In recent years, this new type of plastic product has been widely used in European and American countries, and the demand is increasing. In addition to its widespread daily applications, this product can also be modified or processed according to the needs of users to meet the different requirements of various industries and departments in the national economy.